UNUSUAL CYLINDERS

On this page, we will catalog unusual cylinders which require extra work and charges.

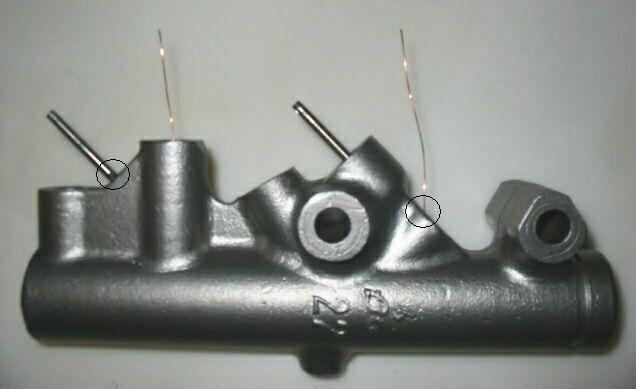

This cylinder is from a 1969 Alfa Romeo GTV. We're told that this was the first year Alfa used a dual-circuit master cylinder in the GTV, and that they had to resort to an unusual configuration of ports to make it fit in place of the older single-circuit cylinder. In order to get the lines coming off the cylinder in the right directions, they drilled intersecting holes for the inlet ports and compensating ports at each end of the cylinder, then plugged one hole at each end. The first picture is of the cylinder after sleeving and before the plugs were installed. We have put bits of copper wire into the compensating ports and drill bits in the inlet ports to show the intersections. The circles show the holes that get plugged.

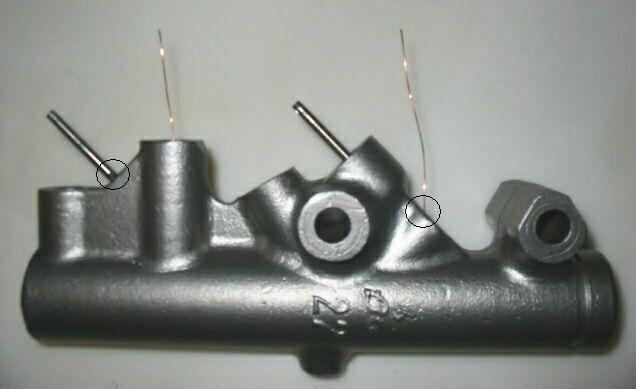

The next picture shows the old and the new plugs. With the permission of this customer, we tapped the hole for the secondary inlet port, which is the second hole from the left, about 1/2" deep and used a setscrew to plug it. The factory drove in an aluminum plug sealed with adhesive. The setscrew will make it easier to service the cylinder in the future should it be required. The access hole for the primary compensating port is the last hole on the right. It has a shallow counterbore about 1/2" in diameter, which the factory filled with a steel plug. We fitted the counterbore with a brass plug, driven in and sealed with adhesive. Neither of these ports is under pressure other than that developed between the reservoir and the cylinder...perhaps 1psi or so. We charged an extra $20 to remove the old plugs and make and install the new ones.

Dexter Trailer Cylinder/Backing Plate

We're told these are from industrial trailers. We see them in 1-1/4" and 1-3/8" diameters. One customer has us sleeve both sizes to the larger diameter. That's not a problem, and we make no extra charge for it. They're a real pain to fixture up for boring and we do charge $15 extra for that.

There are various styles of these tin-can master cylinders, used mostly on British cars. The sheet metal can must be removed from the steel tube before sleeving so we can clean the inside of the can properly and so we can re-drill the fluid ports. Then the can must be re-soldered to the tube in the proper orientation. We charge $30 to remove, replace, and pressure-test the can. Note that on rare occasion the tin can may be badly rusted to the point that we are not able to get it to hold pressure. We try to identify these before we start the job. Also note that rusty cans will continue to deteriorate. We cannot be responsible for leaks that occur in the wall of the can after the cylinder is put back into service.

Early Wagner-Lockheed Box-Type Master Cylinder Assembly

These were used in a number of makes in the late '20s and early '30s. The box is the reservoir. The cylinder itself can be a one-piece casting or a two-piece assembly consisting of a head casting and a steel tube. Both types of cylinder are shown. We charge regular single-circuit prices for sleeving either type. We have seen these in 1-1/4", 1-3/8", 1-1/2", and 1-3/4" diameters. If we receive the entire assembly for sleeving or for a complete rebuild, we charge an additional $40. This is primarily because of the many pieces to disassemble, clean, and reassemble. If you send the cylinder only, we will include a special-size EPDM o-ring to replace the original seal on the actuating shaft.

We recommend that you send both the head casting and the tube if you have the two-piece cylinder, even if you have removed the tube from the head. The factory machined the slot and the compensating port after assembling the tube and head so that the slot and port were on top. When they are disassembled, the registration is lost, and the slot and port will most likely no longer be on top when reassembled. We assemble the parts with a new aviation gasket, and machine the end of the tube as necessary so that the slot and port will be on top when the tube is tight..

Below at left is a picture of the cylinder head with a new copper/asbestos aviation gasket inserted. The original gasket is aluminum with a raised circular contact area where the residual valve gasket seals. Every one we have seen has been badly corroded, and the one pictured at right is typical. The black line points to the small remaining remnant of the raised circle. It is of course impossible for the residual valve to seal properly against such a corroded surface, so it is very important that the tube and head be disassembled and the old gasket be removed. In some cases the cast iron surface under the gasket is in good condition. In others, we must machine the area where the valve seals. Either way, when we are done the valve will seal well, the slot and port will be on top and the cylinder will work properly.

EBay vendor Classic and Exotic Service has a number of parts and kits for these cylinders. Click here to go to their eBay store or here to go to the online catalog on their website.

|

|

|

Wheel Cylinders with Emergency Brake Slots

The upper pair of wheel cylinders is assembled with a lever through the opening which activates the brake shoes when the emergency brake is applied. The rectangular opening must be milled out after the sleeve is installed, and we charge $15 per cylinder for this work.

The lower pair of cylinders has a fork in which a similar lever pivots. In this design, however, the lever is external to the bore, and there is no extra work or charge involved.